How We Make Natural Soap & Shampoo Bars:

A Labor of Love

My journey into natural skincare began in 2001 with soap-making. I started small, with a mold that made just 8 bars, but I was instantly hooked. I quickly discovered the profound impact of natural ingredients on my skin. This experience fueled my dedication to crafting natural soaps that nourish, protect, and truly care for the skin.

Have you ever wondered how we make natural soaps without synthetic fragrances, artificial colors, or detergents?

Our soaps and shampoo bars are handcrafted in small batches using the traditional Cold Process Method.

This time-honored technique involves mixing and blending ingredients without any external heat.

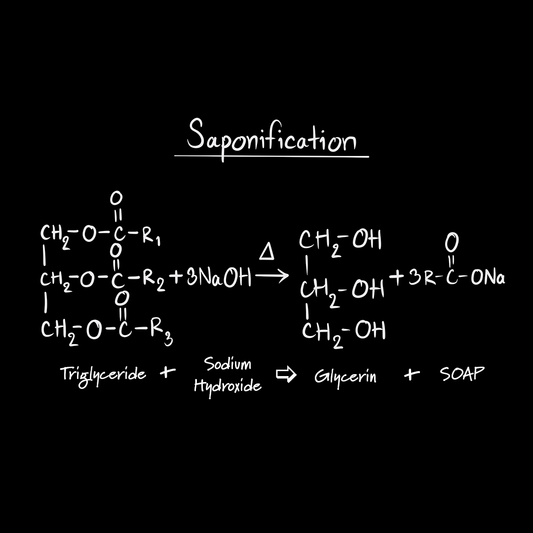

True soap is born from a natural chemical process called saponification. This process involves combining an acid (the fatty acids from oils and butters) with an alkaline substance (sodium hydroxide) dissolved in a liquid. The resulting reaction transforms these ingredients into fatty acid salts (soap), glycerin, and a small amount of water. One of the most beneficial by-products of saponification is glycerin, a natural humectant that helps to moisturize and soften your skin.

Learn More Blog: The Chemistry of Natural Soap Making

I know you are asking . . . is there lye in my soap? The answer is NO!

But here is the important part: Real soap cannot be made without lye (sodium hydroxide). Any "lathering cleansing soap-type product" made without sodium hydroxide (lye) is not soap; it is a synthetic detergent. Natural liquid soaps are made with potassium hydroxide.

Detergents are fine as household cleaners, but do you really want to wash your skin with the same ingredients used to clean floors or dishes?

Sometimes people get nervous when they see sodium hydroxide (lye) on the ingredient list, so some soapmakers use the term "saponified oils" to avoid mentioning the lye. The term indicates that the oils have been mixed with a lye solution, so it is still the same chemical process. We're all about transparency, so you'll always know exactly what's in our soap.

Learn More Blog: Is There Lye In Natural Soap? Won't It Harm My Skin?

Rest assured, there is NO lye in a bar of Chagrin Valley Natural Soap. When saponification is complete, the lye and fat molecules have combined and chemically changed into completely lye-free soap and glycerin.

So, how can we be sure that no lye remains in our soap? We begin with a deep understanding of proper formulation, add extra oils and butters, known as superfat (see below), and inspect and test every batch. Then we use the most reassuring test of all, using the soap or shampoo bar on our own skin.

Side note: While "lye" and "sodium hydroxide" are often used interchangeably, technically, "lye" refers to the solution of sodium hydroxide and water or water-based liquid.

How We Formulate a Soap Recipe

In our approach to soap making, science takes center stage. While following a pre-existing recipe can yield satisfactory results, formulating an exceptional soap from scratch demands a deep understanding of the underlying chemistry.

This involves meticulously researching and balancing the complex interactions between ingredients to achieve the ideal qualities, such as rich lather, effective cleansing, and moisturizing properties.

Since an unbalanced formula can lead to poor-quality soap, it is essential to have a thorough grasp of the properties and fatty acid profiles of various soapmaking oils, as well as their individual reactions with lye.

The properties of an oil are directly tied to its fatty acid composition, and each type of fatty acid imparts unique characteristics to the soap. For instance, coconut oil owes its exceptional lathering ability to its high content of lauric acid.

With this knowledge, we carefully select the oils and butters that will work in harmony to produce a soap that meets our rigorous standards.

The base oils used in our soaps are all USDA-certified organic. Each oil is chosen for the special properties it gives to the soap. For example:

- organic olive and sunflower oils are gentle, conditioning, and moisturizing

- organic coconut oil provides natural cleansing and bubbly, fluffy lather

- organic sustainable palm oil creates a hard bar with creamy and conditioning lather

- organic castor oil creates a dense, creamy, bubbly lather that conditions and moisturizes

By carefully balancing cleansing, conditioning, and moisturizing oils—and staying rooted in the science of soapmaking—we can craft natural soap recipes that perform beautifully and provide a luxurious and nourishing experience for the skin.

To further enhance our soap creations, we incorporate natural ingredients that can modify the soap's properties, such as texture, color, scent, and skin benefits. This allows us to tailor each soap recipe to achieve specific desired features, resulting in a truly customized final product.

The Soap Making Process

Any soap or shampoo is only as good as the ingredients used to make it!

We begin with the finest ingredients: fresh, nutrient-rich organic plant oils and botanical butters, sourced sustainably and ethically.

The plant oils and butters, gently warmed until melted, are sometimes infused with herbs, spices, or botanicals.

Next, we slowly blend the warmed oils with an alkaline lye/liquid solution, carefully crafting the perfect mix.

Our natural soap recipes often feature unique liquid ingredients, in addition to water, blended with sodium hydroxide. These liquids may include herbal teas, fruit or vegetable juices, goat milk, coconut milk, yogurt, beer, or even brewed coffee. Each carefully selected liquid adds distinct properties and benefits to our artisanal soaps.

The soap batter is mixed until it reaches the proper consistency and an emulsion is formed. An emulsion is a mixture of two or more liquids that do not normally mix, such as oil and water.

Then, depending on the soap recipe, we add a range of beneficial ingredients, including organic essential oils, purifying clays, bamboo charcoal, chocolate, and more.

The soap mixture is then poured into insulated molds, where it sets for 2-3 days. Once set, the soap is cut into bars and allowed to naturally air cure for 8 to 12 weeks.

Superfat

The science of soapmaking tells us that every unique recipe requires a precise fat-to-lye ratio to ensure all the lye is transformed into soap during the saponification process.

But if the formula is too exact, no extra oil is left behind, resulting in a bar with 0% superfat and none of the nourishing qualities we love. Worse yet, even a tiny miscalculation could leave excess lye in the bar.

The ratio of fats to sodium hydroxide (lye) is critical. To ensure our soaps are not only extra mild and nourishing but also completely lye-free, we use a technique called superfatting.

Superfatting means adding more oil than the lye can convert into soap. These leftover oils—called unsaponified oils—become suspended between the soap molecules and are released onto your skin as you wash.

We believe that superfatted soaps and shampoo bars deliver a rich, silky lather and a remarkably gentle cleansing experience – a testament to the meticulous care and precision that goes into crafting every recipe.

Most cold-process soapmakers aim for a 5% superfat, leaving just a little oil behind after saponification. We take a different approach, formulating our bars with a higher superfat percentage.

Each of our recipes is carefully balanced, considering both the oils used and the bar’s intended purpose.

Each of our recipes is carefully balanced, considering both the oils used and the bar’s intended purpose.

For example, our facial soaps, shaving bars, and baby soap have a higher superfat than our everyday body bars, tailored to their specific needs.

The Scents & Colors of Natural Soap

Many of our soaps are unscented, yet they still boast distinct, natural aromas thanks to unrefined oils and butters, grains, flowers, spices, herbs, honey, and other natural ingredients.

For our scented soaps, we exclusively use pure, organic essential oils. We never use fragrance oils (parfum) or "nature identical" oils, ensuring that our soaps not only smell wonderful but also remain true to their natural ingredients.

Learn More Blog: Why We Use Only Real Plant Essential Oils

Our soap colors come from nature, using juices, teas, spices, botanicals, or clays to create a range of earthy hues.

Why Do Handmade Natural Soaps Need To Cure?

Saponification and Curing are not the same. Saponification, the natural process that transforms fats and lye into soap, occurs rapidly, with 96-99% of the reaction usually complete within the first 48 hours.

At this point, the bars are safe to handle, and most soaps could be used after just a few days. However, the quality of this young soap will be quite disappointing. It may feel harsh on the skin, produce minimal lather, be very soft, and have a shorter lifespan compared to a fully cured bar. Patience is key, as allowing the soap to cure enables it to reach its full potential.

So What is Soap Curing?

Carefully crafted and never rushed, each fresh soap or shampoo bar is allowed to cure slowly and naturally, maturing over time.

As it cures, the last of the saponification process comes to a close, the excess water evaporates, and the naturally occurring glycerin becomes more concentrated. The bars gradually harden and develop their crystalline structure.

The curing time for each recipe of cold-process soap is different. While some soapmakers use a 4-week cure, we believe our longer, slower curing time of 8 to 12 weeks ensures a milder, harder, longer-lasting bar with a rich lather.

Although as our soaps sit waiting for a new home, they will continue to shrink in size, this longer curing time results in a bar of soap with exceptional mildness and luxurious lather.

Our Chagrin Valley Natural Soaps & Shampoo Bars

The result of our painstaking, meticulous process is a mild, rich, moisturizing soap that feels creamy in your hands, offers a magnificent long-lasting lather, and leaves your skin clean, soft, silky, and radiantly healthy.

Our natural soap and shampoo bars, made using ingredients that are Certified Organic, non-GMO, cruelty-free, sustainably produced, and ethically traded, contain only the ingredients that they need.

Our soap and shampoo bars contain NO alcohol, detergents, sulfates, synthetic fragrances, synthetic colors, or preservatives.

Is There Lye In Natural Soap? Won't It Harm My Skin?

Are All Handmade Soaps The Same?

How Does Natural Soap Create Lather?

12 Reasons To Use Natural Soap

Find joy in our full range of Organic Soaps.

This blog, originally published in March 2015, has been updated.